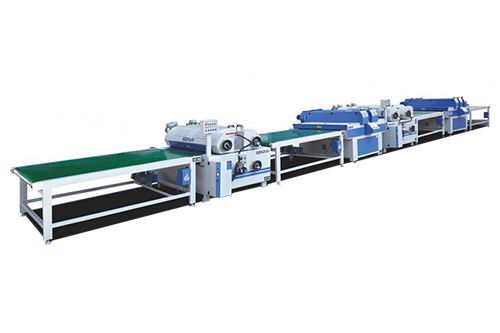

This fully automatic coating line is a great flat glass coating solution incorporating a combination of roller coating and IR drying technologies. Thanks to the expertise and know-how gained in the glass coating field, verified during years of activity, the glass roller coating and drying line is highly configured to enable the coating process to be carried out reliably and precisely.

Reasonably integrating glass sheet loading, roller coating, transfer conveying, IR drying, cooling and unloading, this automatic glass roller coating line not only meets rigid standards of the industry, but also offers high level of automation and flexibility.

We know that different glass manufacturers have different needs for glass coating. With that in mind, the design of this glass roller coating line allows users to select the equipment width with modified configurations to suit their demands and budget. In addition, our glass coating line can be provided in either straight line layout or configured with transfer conveyors to accommodate the routing in the glass processing plant.

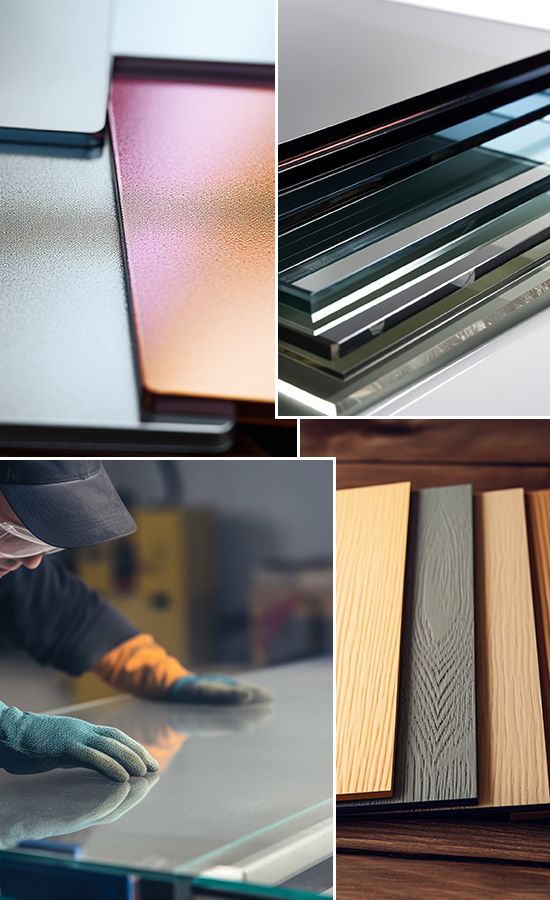

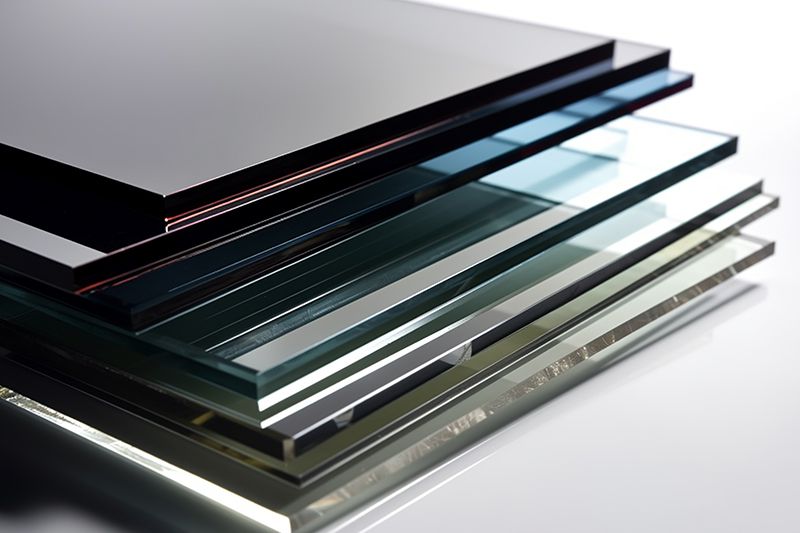

- Premium Quality

The coated glass sheet features a smooth surface and an even coating layer, without color difference. The colored painted can be coated on glass to achieve no light transmission. - High Efficiency

A single glass coating line can achieve a daily output capacity in range of 800 to 2000 meters (8 hours/day) - Reduced Labor Intensity

Roller coating process assures faultlessness of four edges without coating defects and oil stains, so that the need for manual grinding and polishing is eliminated therefore enabling the coated glass sheets to be directly packaged. - Low Cost

Paints and coatings are recycled, reducing waste and removing the need to frequently replace damaged screens, which would save both cost and time. - Environmental Sustainability

Roller coating is considered as an ideal alternative to spray coating and screen printing or other conventional coating methods in terms of environmental concerns. Roller coating helps reduce the environmental impact since it can prevent paints from spattering, it is in full compliance with the requirements of environmental regulations.

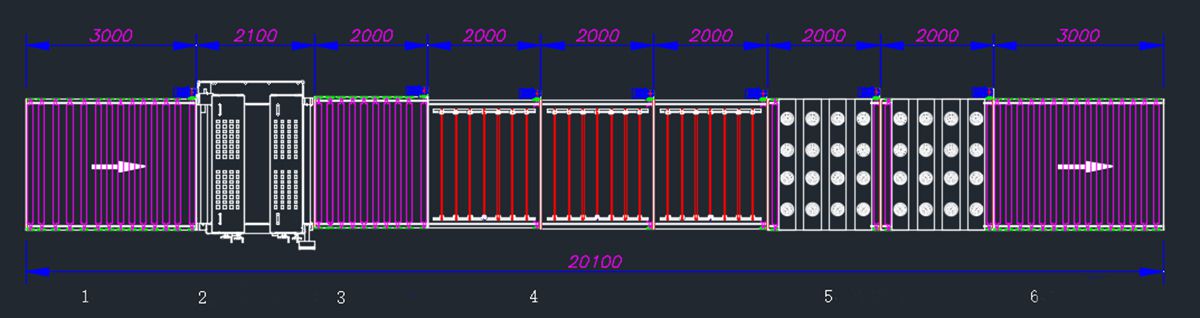

The entire glass coating line consists of glass loading machine, roller coater, transfer conveyor, IR dryer, cooling system and glass unloading machine, which are illustrated in the following layout diagram.

-

1Glass Loading Machine

-

2Double Roller Coater

-

3Transfer Conveyor

-

4IR Dryer

-

5Cooling System

-

6Glass Unloading Machine

| Working Environment | Temperature | 10°C (min.) 35°C (max.) |

| Humidity | 60% (average) 75% (max.) | |

| Working Time | 24h/day, 7days/week, 50weeks/year | |

| Power & Air Source | Power Supply | 3-phase/N/PE, 380V/50Hz |

| Voltage | 24volt | |

| Voltage Fluctuation | +/-10% | |

| Compressed Air | 6 bars (no water, oil free) | |

| Glass Sheet Size | Width | Max. 2500mm |

| Length | Min. 600mm | |

| Thickness | 2.5-19 mm | |

| Line Performance | Glass Handling (before entering coating line) | Cutting/edge grinding/cleaning |

| Glass Transferring | Short edge guiding | |

| Changeover time | Approx. 15-20 min | |

| Conveying Height | 850mm ±50mm | |

| Operating Side | A direction or B direction (optional) | |

| Noise Level | ≤85 dB (A) |

-

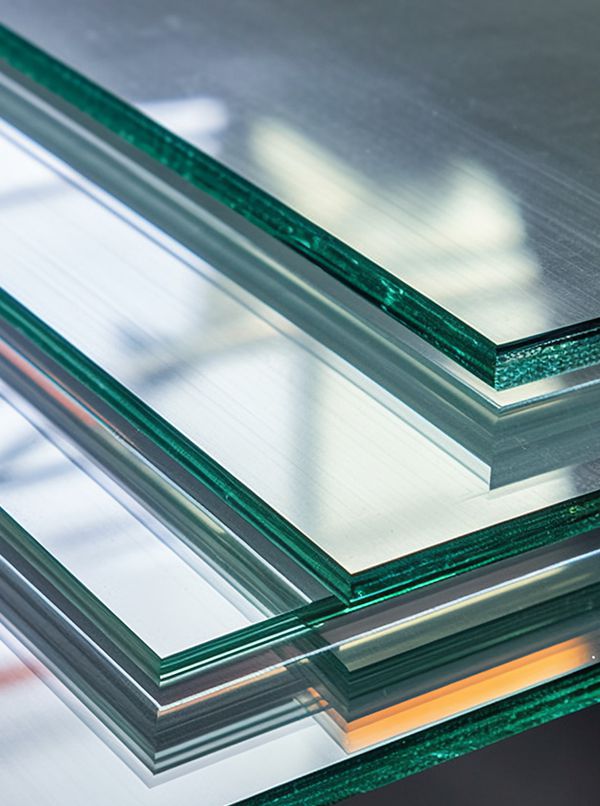

- Double Roller Coater for Glass

Model: SR-R2PL Series

This double roller coater is specifically designed for applying coatings on flat glass sheets. It utilizes two application rollers to transfer coatings on flat workpiece surface evenly, with less paint consumption and higher productivity.

HMI interface control system enables parameters to be input manually according to the working conditions. Learn More

-

- IR Dryer

Model: IR Series

This IR dryer is a glass drying tunnel primarily used in glass coating line for drying and curing flat glass after coating. There are two standard sections in the infrared drying tunnel, i.e. IR heating zone and observation zone. Variable speed drive is adopted in conveyor for stepless speed adjustment, and drying temperature can be freely set within a range of room temperature to 250℃. Specifications of IR-2600 Glass Drying Tunnel (as an example)

Drying Tunnel Width: 3100mm

Feeding Width: 2600mm

Drying Tunnel Length: 6000mm

Feeding Speed: 1-12m/min

Temperature Adjustment Range: Room temperature to 250℃

Medium-Wave Infrared Tube: 0.8×54=43.2kW

Motor Power: 4.5kW

Total Power: Approx. 47.7kW

Dimensions: Approx. 6000×3000×1350mm Learn More

-

- Cooling Conveyor

Model: LQ Series

The cooling conveyor is used as a cooling system to work in glass roller coating line for cooling glass sheet after infrared drying. The conveyor is equipped with variable speed drive to control the conveying speed during cooling. Learn More

-

- Glass Loader, Unloader and Transfer Conveyor

Model: SP Series, XP Series, GT Series

Roller conveyors are typically used to load, unload and transfer flat glass sheets prior and after coating in the glass coating line. Variable speed drive is used to control the conveying speed. Learn More