Plastic products are essential in the construction, automotive, and home appliance sectors, each requiring specialized surface finishing and coating techniques. At Senr, we have extensive experience in manufacturing machinery suitable for coating a variety of plastics, including PET, PMMA, ABS, PS, PA, PVC, PP, and PE. Our approach is customized to the unique characteristics of each type of plastic, ensuring optimal treatment and finishing.

- UV coating on PVC films: Ideal for outdoor advertisements, vehicle graphics, aircraft, high-speed trains, and cars. This coating enhances weather resistance and longevity.

- Coating for calcium plastic boards and flooring: Delivers a durable and aesthetic finish for both building materials and decorative floors.

- Traffic sign coatings: Ensures long-lasting visibility and resilience for road safety signs exposed to the elements.

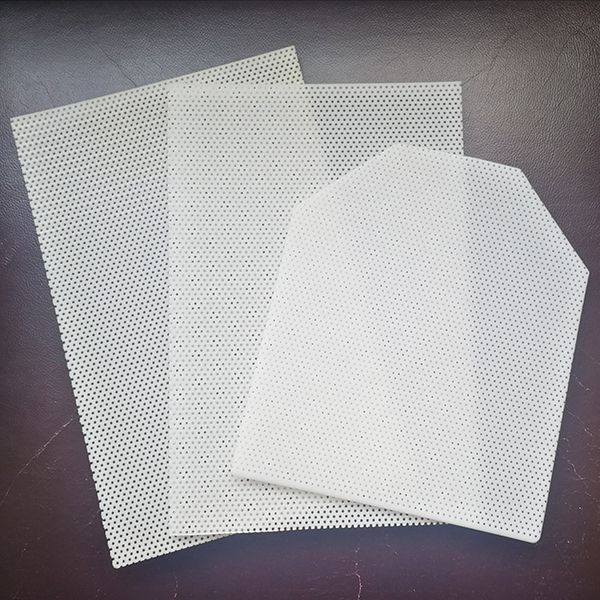

- Isolation layers for medical low-temperature thermoplastic sheets: Provides essential protective coating for medical-grade thermoplastic materials, crucial in healthcare applications.

Plastic materials come in a vast array, from thermoplastic polymers like polypropylene (PP), polycarbonate (PC), polyethylene terephthalate (PET), ABS, and PVC, to PMMA. These materials are molded or extruded into a variety of products. Depending on their size, shape, production volume, and intended use, plastic components undergo various industrial processes. Common stages in their manufacturing include surface spray coating, packaging, industrial printing, and drying and curing of the surface.

In industries such as furniture, construction, or automotive, one of the primary goals of the finishing process for plastics is to enhance the aesthetic appeal and perceived value of the components. There are multiple methods to decorate and customize the final plastic products, allowing for great versatility in design and functionality.

There are various types of plastic coating, with different surface coating technologies employed based on the specific plastic product or desired outcome. Here are some of the most common technologies used:

-

- Plastic Roller Coating Machine Ideal for applying uniform coatings on plastic surfaces.

-

- Plastic Spray Coating Machine Provides precise and even application for various shapes and sizes.

-

- Plastic Surface Curing Machine Ensures that the coatings on plastic surfaces are set and durable.

-

- Industrial Printing Machine Adds detailed graphics and texts to plastic products.

-

- Surface Finishing Line A comprehensive solution that combines multiple processes for a high-quality finish.