-

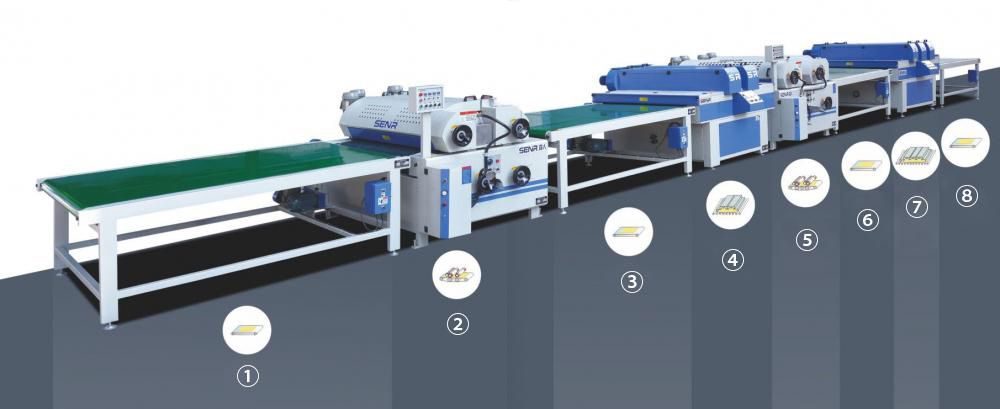

1Conveyer machine

-

2Coating feeder(putty filling)

-

3Conveyer machine

-

4Coating dryer with duel UV lighting lamps

-

5Precision dual roller coater

-

6Conveyer machine

-

7Coating dryer with three UV lighting drying lamps

-

8Conveyer machine

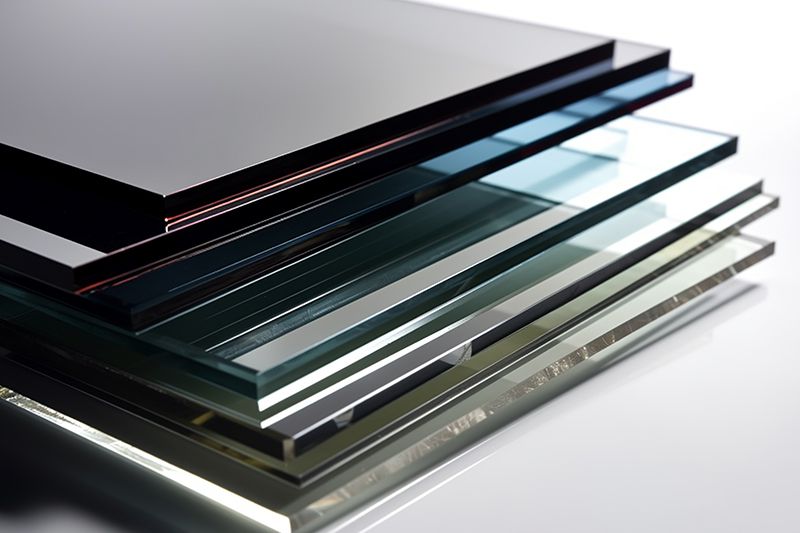

Application

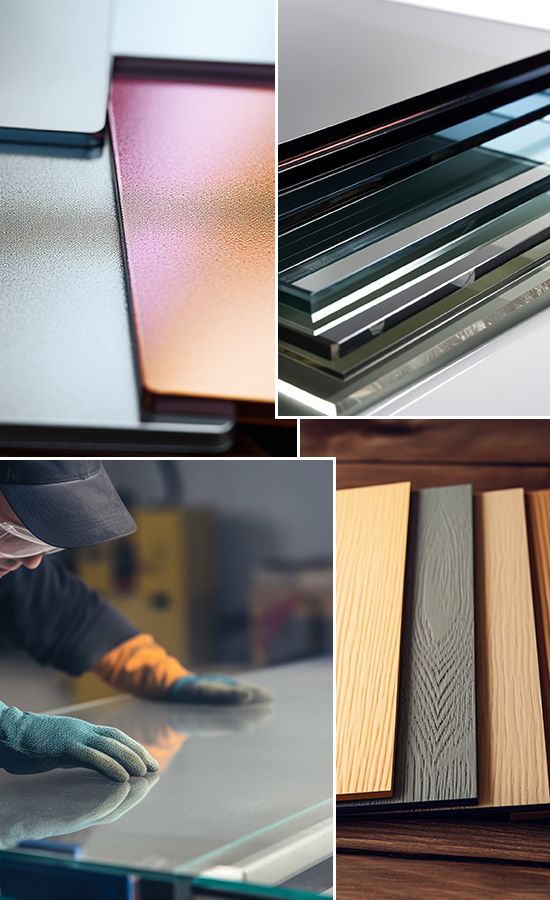

The roller coating system is a dual roller coater design combined with other auxiliary equipment. The system is capable of performing putty coating and primer roll coating for wood materials automatically so as to achieve a flat coating effect. It is particularly suitable for customers in the furniture industry.

Applicable paint

UV paint, water-based paint, PU paint, NC paint, fluorocarbon paint, etc.

Features

- Through reasonable equipment connection and combination, the roller coating line can help users realize fully automatic coating, so as to improve work efficiency and reduce labor costs.

- Using UV environment-friendly coatings or water-based paints is more environmentally protective.

- Aiming at the specific demands of customers, we can change the arrangement manner of the equipment to adapt to the coating of different materials, such as calcium silicate board, glass magnesium board, fiber cement panel, ceramic plate, MDF(medium density fiberboard), polymer composite board, aluminum-plastic plate, colorful glittering glass pane, metal plate etc.

Workflow

-

Conveyer machine: accomplish panels automatic feeding Workflow

-

Coating feeder: evenly roll a layer of putty onto the surface of the panels Workflow

-

Conveyer machine: automatically convey the roller coated panels to the dryer Workflow

-

Coating dryer with duel UV lighting lamps: dries the putty on the surface of the panels instantly Workflow

-

Dual roller coater: rolls the primer evenly onto the surface of the panels to complete the application of primer Workflow

-

Conveyer machine: the panels are automatically delivered to the coating dryer with three UV lighting drying lamps Workflow

-

Coating dryer with three UV lighting drying lamps: with higher power than dryers with two UV lamps, it can thoroughly dry the primer on the surface of the panels Workflow

-

Conveyer machine: the processed plates are automatically transported to the stacking position of finished products.