-

1Conveyer machine

-

2Dual roller coate

-

3Conveyer machine

-

4Curtain coater

-

5Conveyer machine

-

6Tunnel fluid bed coating drying oven

-

7Coating dryer with three UV lighting drying lamps

-

8Conveyer machine

Application

The curtain coating system features our outstanding curtain coater as the main machine and is then matched with additional coating equipment to automatically complete the finish and primer coating of all kinds of flat panel workpieces, including furniture board, cabinet door, bathroom door, showcase board, door frame, window frame, etc.

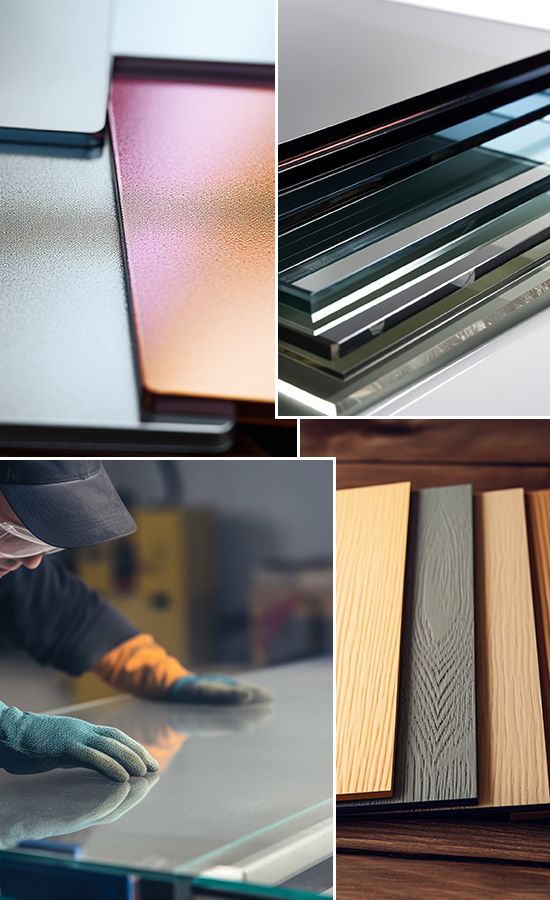

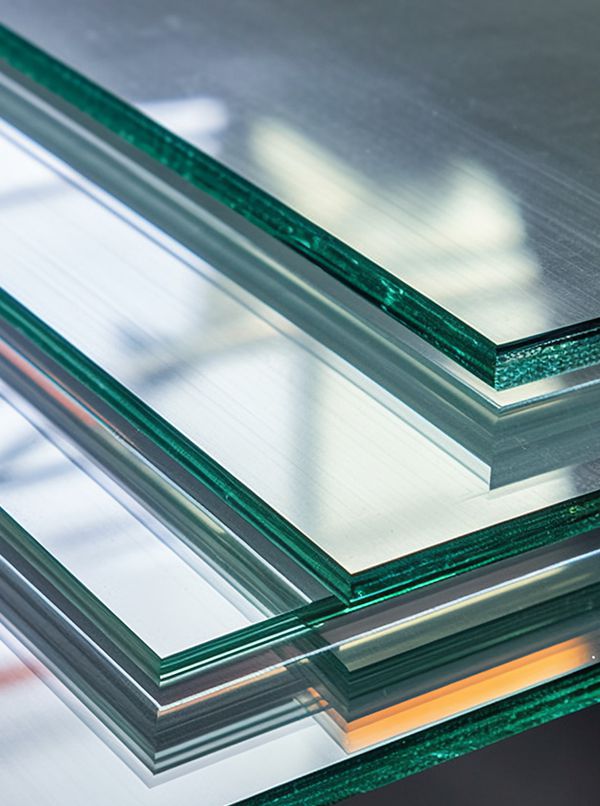

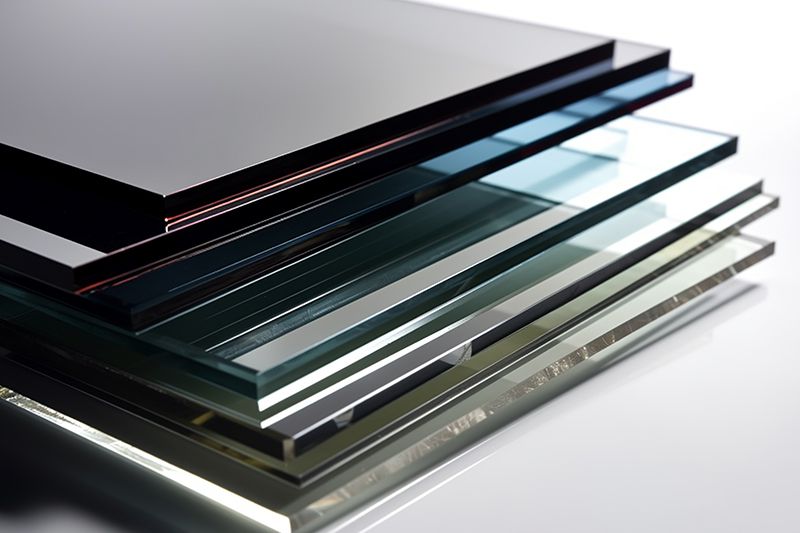

Applicable materials

Calcium silicate board, glass magnesium board, fiber cement panel, ceramic plate, MDF(medium density fiberboard), polymer composite board, decorative plate, aluminum-plastic plate, colorful glittering glass pane, imitation marble, metal plate/coil, etc.

Applicable paint

UV paints, all kinds of water-based paints, PU paints, NC paints, fluorocarbon paints, etc.

Workflow

-

Conveyer machine: realizes automatic panel feeding Workflow

-

Dual roller coater: rolls a layer of sealing primer evenly onto the surface of the panels Workflow

-

Conveyer machine: transports the roller coated panels to the curtain coater automatically Workflow

-

Curtain coater: curtain coats the varnish evenly onto the surface of the panels to complete the finish or primer coating Workflow

-

Conveyer machine: the flow coated panels are automatically conveyed to the tunnel fluid bed coating drying oven Workflow

-

Tunnel fluid bed coating drying oven: levels the surface of the panels that have not been dried, giving them a bright and smooth effect Workflow

-

Coating dryer with three UV lighting drying lamps: instantly dries the UV paint on the surface of the panels Workflow

-

Conveyer machine: the processed plates are automatically conveyed to the stacking position of finished products