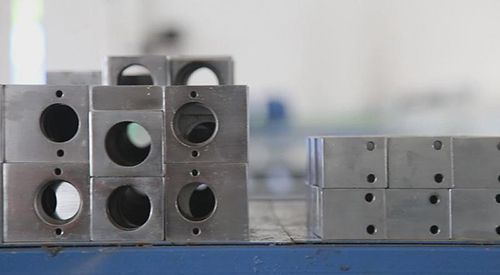

Sheet metal processing workshop

Senr's machining workshop is equipped with a CNC machining center, CNC lathe and other automated equipment for processing the frame, roller and partial metal parts of the coating equipment.

All of main metal parts are independently designed and processed in-house, which guarantees product quality and assembly efficiency. Meanwhile, the application of self-produced parts facilitates the replacement of easily worn parts and reduces the time and cost for maintenance.

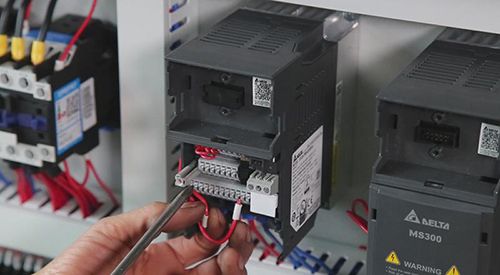

Assembly workshop

For crucial components, for instance drive motor and electrical part, we carefully select products from qualified brand products, such as SIEMENS, Schneider etc.

Senr's assembly workers have with us for many years and they are quite familiar with the construction of equipment. Throughout the assembly process, we insist on conducting all-round quality management for each procedure.

Before the equipment leaves the factory, we will carry out exhaustive check on the overall stability of the equipment, the stationarity of the critical coating parts, as well as the precision of the control part. At the same time, we will let the equipment run continuously for 4 hours, so as to ensure the equipment can be smoothly put into production the instant it arrives at the customer's site.

Coating experience center

We have a dedicated coating experience center equipped to plan and design production flow for customers and allow them to feel and test actual coating effects.