In BYD Auto’s Shanwei plant, we successfully implemented an automatic powder spray coating line, complete with advanced control features for optimal spray precision and efficiency in auto manufacturing.

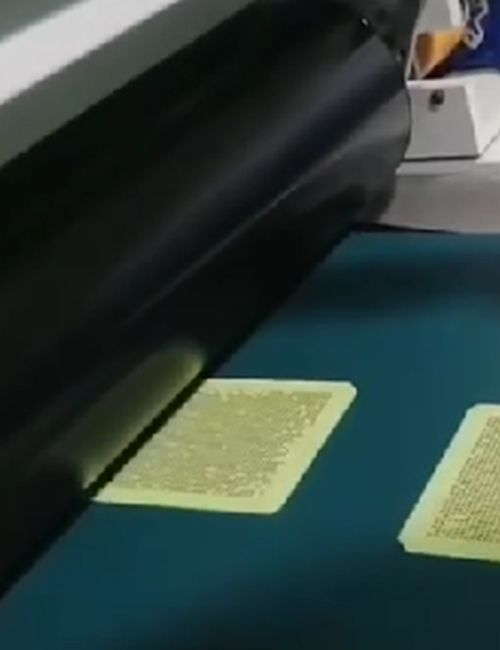

Process: glass loading → roller coating (water-based ink/oil-based ink) → IR drying → air cooling → unloading

Effective width: 2200mm

We developed a specialized aluminum coil coating line for a Chinese customer, featuring processes from unwinding to IR drying and rewinding, catering specifically to the electronic sector’s needs with a 600mm working width.

Process: metal coil unwinding → pre-treatment → roller coating with dielectric ink → IR drying → air cooling → rewinding

Working width: 600mm

Products: aluminum workpieces for electronics

-

- Roller Coating Machine At Senr, we've developed roller coating systems that blend high efficiency with straightforward operation. These systems are engineered to boost production and enhance the final product's quality.

-

- Infrared Drying Tunnel (IR Dryer) The infrared drying tunnel is an essential equipment in modern coating processes. It's suitable for the post-application phase of roll coating, spray coating, and curtain coating.

For a Turkish client, our tailor-made solution included a roller coating machine, IR dryer, and film laminator, designed to efficiently coat magnesium oxide panels.

-

- Roller Coating Machine Roller coating stands out as a top choice for treating flat surfaces. At Senr, we've developed roller coating systems that blend high efficiency with straightforward operation. These systems are engineered to boost production and enhance the final product's quality. Learn More

-

- Infrared Drying Tunnel (IR Dryer) The infrared drying tunnel is an essential equipment in modern coating processes. It's suitable for the post-application phase of roll coating, spray coating, and curtain coating. This drying machine specializes in efficiently volatilizing diluents and bubbles from the surface coating, ensuring a smooth and even finish before proceeding to the drying stage. Learn More

-

- Film Laminator The coating laminator is used to apply protective films onto a coated panel, thus avoiding scratch or any damges caused during transportation or installation. Learn More

Our solution for effectively applying water-based anti-corrosion paint on iron sheets involved a roller coating machine and IR dryer, ensuring consistent and high-quality coating.

-

- Roller Coating Machine Roller coating stands out as a top choice for treating flat surfaces. At Senr, we've developed roller coating systems that blend high efficiency with straightforward operation.

-

- Infrared Drying Tunnel (IR Dryer) The infrared drying tunnel is an essential equipment in modern coating processes. It's suitable for the post-application phase of roll coating, spray coating, and curtain coating.